Dezhou Shangqi Expanded Metal Machine Factory

products show

contact us

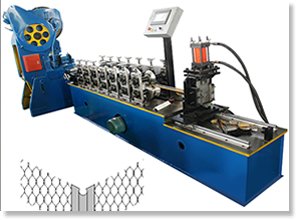

Corner Bead Machine for Processing Galvanized Steel Angle Beads

The machine is designed for processing of expanded metals into plaster beads / corner beads / angle beads. Corner beads production line is supplied mainly with decoiler, forming machine, cutting devices.

Main Parameters:

1: Installing SIze: 15000x1100x1700mm

2: Total Net Weight: 2400kg

3: Cotroller: Relay Control

4: Total Motor Power: 10.2 kw

5: Speed: 10-18000 mm/min

| Material | |

| Thickness | 0.3-1.0mm |

| Feeding width | as customer request |

| Applicable material | GI/PPGI/AL |

| Manual Un-coiler | |

| Max Capacity | 5 Ton |

| Features | Manual with brake |

| Main Forming System | |

| Motor Power | 5.5KW forming system |

| Roller material | 45# steel, precision machined, mirror treatment, coatd with rigid chrom |

| Main forming shaft | Φ75mm, solid 45# tempering steel |

| Frame | 350H steel plate welding |

| Transmission | by chain-and-gear |

| Measuring accuracy | +/- 2 mm/M |

| Producing speed | 4-8m/min |

| Working procedure | decoilering -- forming -- moulding -- cutting -- product finished |

| Hydraulic Cutting Device | |

| Cutting way | Post cut, stop to cutting |

| Cutting material | Cr12 with harded quenched and tempered, two piece of cutting blades |

| Motor power of Oil pump station | 4KW |

| Electrical System | |

| Control system | PLC controller(import brand) touch screen |

| Power | 380V 50Hz (as per local requirement) |

| Extra | |

| Dimesion(L*W*H) | 6500mm * 1300mm * 1100mm |

| Weight(Ton) | 3.5T |

Machine for V Keel Angle Forming

Machine for V Keel Angle Forming  I Beam Angle Forming Machine

I Beam Angle Forming Machine  Machine with Decoilers

Machine with Decoilers  Production Line for Galvanized and Stainless Steel Angle beads production

Production Line for Galvanized and Stainless Steel Angle beads production © Copyright Dezhou Shangqi Expanded Metal Machine Factory

Metal sheet stretching, punching, flattening, slitting - We value your business - Contact us now.